Products

Contact Us

Service Tel:+86-371-53762053

Tel/whatsapp/wechat:+86-13674998188 (24 hours online)

E-mail: zhengzhouyuxi@yuximachine.com

Add:Economic And Technological Development Zone, Zhengzhou, Henan, China (Mainland)

Tel/whatsapp/wechat:+86-13674998188 (24 hours online)

E-mail: zhengzhouyuxi@yuximachine.com

Add:Economic And Technological Development Zone, Zhengzhou, Henan, China (Mainland)

Skype:

yuxi.zhengzhou

products

All Types Feed Pellet Mill

Feed Pellet Line

Feed Pellet Equipment

Storage System

Wood Pellet Line

Wood Pellet Equipment

We can provide the working sites of our customers' in many countries, please contact us if necessary.

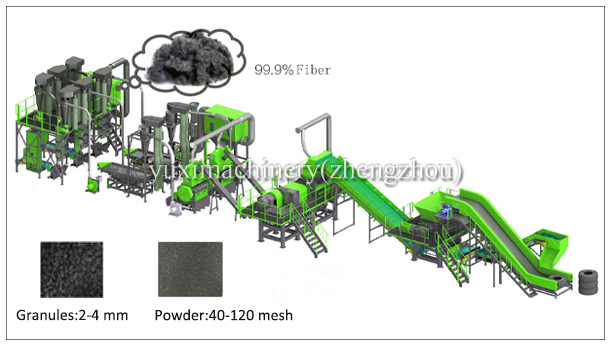

●Conveyor-Transport the tire strips to the secondary shredder

●Conveyor-Transport the tire strips to the secondary shredder

●Secondary Twin shaft shredder---shears the strips into smaller more uniform sized shreds

●Recirculation System---To control the size of shreds going to the Raspers.

●Raspers-reduce the shreds into 15-20mm chips and liberates steel from the rubber.

●Overbelt Magnet--separation of liberated steel from the rubber chips.

●Vibratory Feeder--transports the rubber chips

●Granulator--size reduction of the chips to 1-4mm granules and liberates the textile fraction to allow separation.

●Vibratory Screen-sorts the granules by size and removes the majority of textile.

●Zig-Zag classifer-removal of remaining textile.

●Drum magnet-removal of remaining steel fines

●Big-bag station

●Central De-dusting unit--removes dust and fines from the system and filters the air before returning it to atmosphere

●Control Panel

●The rubber crumbs,steel and fibre can be separated automatically.

●Adopt PLC control system,it is simple and easy to control and maintain,for example,it is only need 2-4persons to operate a tire recycling(granule)production line with 500-10000kg/h capacity.

●Low energy consumption.Long service life,high utilization,Multiple maintenance.

●User-friendly design,safe and secure.

- Contact Us

- Add:Economic And Technological Development Zone, Zhengzhou, Henan, China (Mainland)

- Tel/whatsapp/wechat:+86-13674998188 (24 hours online)

- Fax:+86-371-53762053

- Skype : yuxi.zhengzhou

- E-mail: zhengzhouyuxi@yuximachine.com

- Follow Us

Copyright 2003. Yuxi Machinery Equipment(zhengzhou) Co.,Ltd. ©